Offering the best quotes for your research!

New and used scientific instruments

🚚 Shipping Worldwide 🌎

✉️ info@questpair.com

Do you have items to sell? Post them on QuestPair and reach thousands of potential buyers!

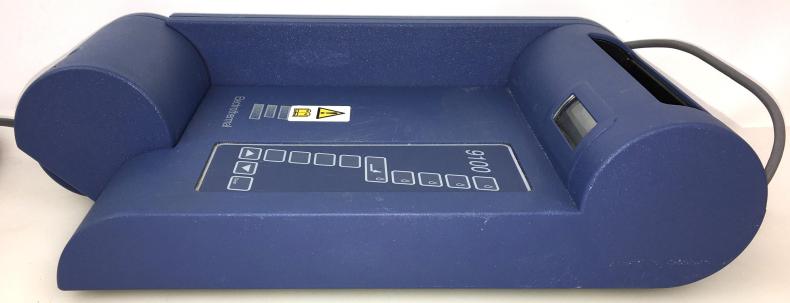

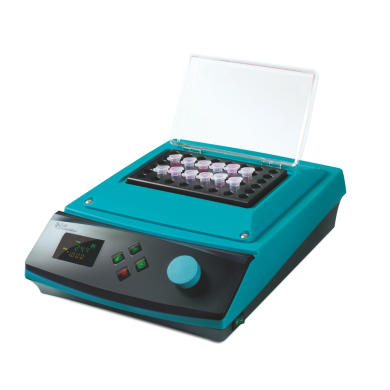

Post New ItemGeneral laboratory equipment

Equip your lab with our extensive range of general laboratory equipment. From basic essentials to advanced instruments, our selection ensures that your lab is fully equipped to handle a wide array of scientific tasks with precision and efficiency. Shop Now!

Didn't find what you're looking for?

Our sales team specializes in sourcing custom and hard-to-find products to meet your exact specifications.

Extensive supplier network

Quality guaranteed

Dedicated support

Didn't find what you're looking for?

Our sales team specializes in sourcing custom and hard-to-find products to meet your exact specifications.

Extensive supplier network

Quality guaranteed

Dedicated support

Didn't find what you're looking for?

Our sales team specializes in sourcing custom and hard-to-find products to meet your exact specifications.

Extensive supplier network

Quality guaranteed

Dedicated support

Your One-Stop Shop for General Laboratory Equipment

At QuestPair, we offer a vast selection of general laboratory equipment that forms the backbone of any scientific research or testing facility. Our collection includes everything from basic instruments to specialized devices, all designed to meet the rigorous demands of modern laboratories. Whether you're setting up a new lab or upgrading existing equipment, you'll find what you need to ensure accuracy, safety, and efficiency in your work.

Why Choose QuestPair's General Laboratory Equipment?

- Wide Range of Products: We provide a comprehensive selection of lab equipment, from essential glassware and centrifuges to precise scales and reliable lab ovens.

- Quality and Reliability: Our products are sourced from trusted manufacturers and are designed to deliver consistent performance, ensuring accurate and repeatable results.

- Cost-Effective Solutions: We offer competitive pricing on all general laboratory equipment, making it easier to equip your lab without breaking the budget.

- Expert Support: Our team of experts is available to help you select the right equipment for your specific needs, ensuring optimal performance in your lab.

Explore Our General Laboratory Equipment Categories

Our general laboratory equipment is categorized to help you find exactly what you need quickly and easily:

- Lab Heating and Cooling Systems: Ensure precise temperature control in your experiments with our reliable heating and cooling systems, designed for a wide range of laboratory applications.

- Lab Pumping Systems: Our selection of pumping systems provides efficient and reliable fluid handling solutions, essential for maintaining flow rates and transferring liquids safely.

- Lab Stirrers: Achieve consistent mixing with our high-quality stirrers, suitable for various viscosities and volumes in both simple and complex applications.

- Lab Centrifuges: Explore our range of centrifuges, perfect for separating substances with precision in research, clinical, and industrial settings.

Equip Your Laboratory for Success with QuestPair

Having the right equipment is essential for the success of any laboratory. QuestPair offers a wide range of general laboratory equipment that meets the highest standards of quality and performance. Whether you’re conducting basic experiments or advanced research, our equipment ensures that you have the tools you need to achieve accurate and reliable results.

Need Help Choosing the Right Equipment? Our knowledgeable team is here to assist you in selecting the best general laboratory equipment for your specific applications. Contact us for expert advice and personalized recommendations.

Customer Service

Here to help you with: Product Inquiries, Shipping & Support, Technical Support, Business Inquiries and Press.

We are available to assist you Mon-Fri, 10am - 5pm CET.