Offering the best quotes for your research!

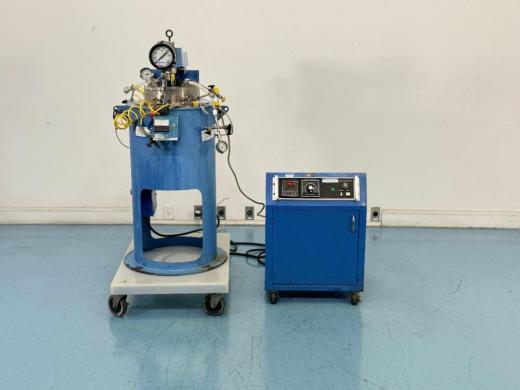

New and used scientific instruments

🚚 Shipping Worldwide 🌎

✉️ info@questpair.com

Do you have items to sell? Post them on QuestPair and reach thousands of potential buyers!

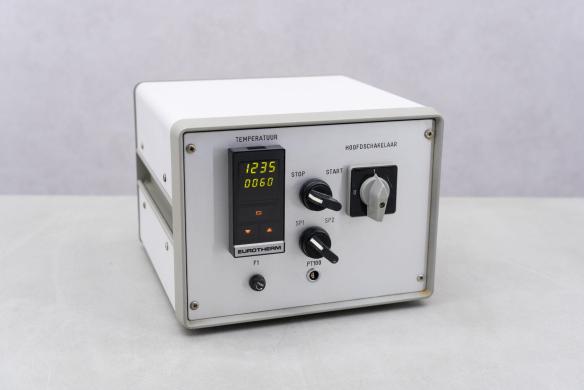

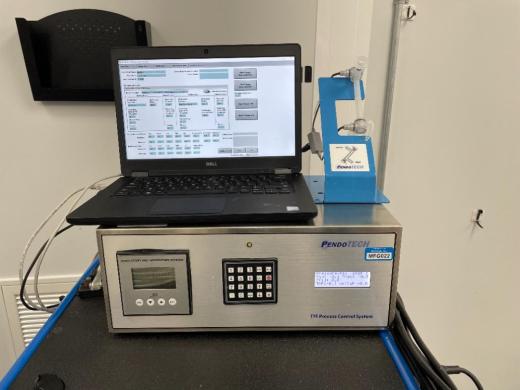

Post New ItemProcess controls

Didn't find what you're looking for?

Our sales team specializes in sourcing custom and hard-to-find products to meet your exact specifications.

Extensive supplier network

Quality guaranteed

Dedicated support

Didn't find what you're looking for?

Our sales team specializes in sourcing custom and hard-to-find products to meet your exact specifications.

Extensive supplier network

Quality guaranteed

Dedicated support

Didn't find what you're looking for?

Our sales team specializes in sourcing custom and hard-to-find products to meet your exact specifications.

Extensive supplier network

Quality guaranteed

Dedicated support

Customer Service

Here to help you with: Product Inquiries, Shipping & Support, Technical Support, Business Inquiries and Press.

We are available to assist you Mon-Fri, 10am - 5pm CET.