Offering the best quotes for your research!

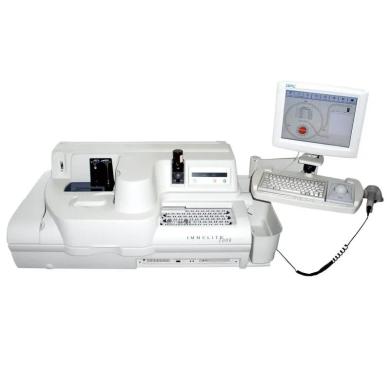

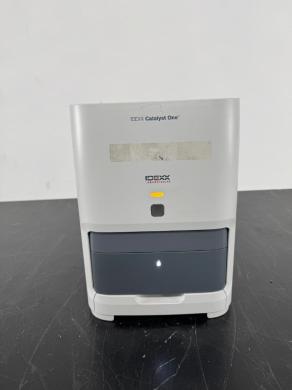

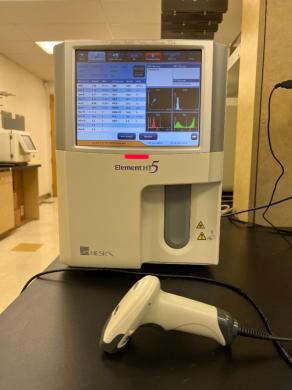

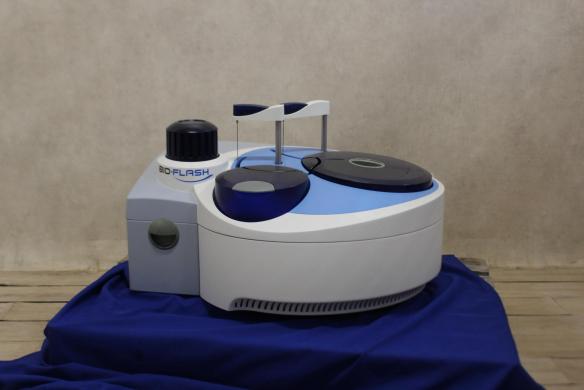

New and used scientific instruments

🚚 Shipping Worldwide 🌎

✉️ info@questpair.com

Do you have items to sell? Post them on QuestPair and reach thousands of potential buyers!

Post New ItemMedical diagnostic instruments - other

Didn't find what you're looking for?

Our sales team specializes in sourcing custom and hard-to-find products to meet your exact specifications.

Extensive supplier network

Quality guaranteed

Dedicated support

Didn't find what you're looking for?

Our sales team specializes in sourcing custom and hard-to-find products to meet your exact specifications.

Extensive supplier network

Quality guaranteed

Dedicated support

Didn't find what you're looking for?

Our sales team specializes in sourcing custom and hard-to-find products to meet your exact specifications.

Extensive supplier network

Quality guaranteed

Dedicated support

Customer Service

Here to help you with: Product Inquiries, Shipping & Support, Technical Support, Business Inquiries and Press.

We are available to assist you Mon-Fri, 10am - 5pm CET.