Offering the best quotes for your research!

New and used scientific instruments

🚚 Shipping Worldwide 🌎

✉️ info@questpair.com

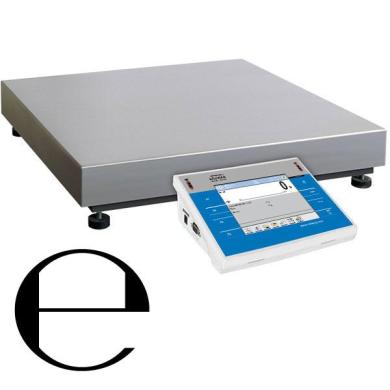

Radwag WLY 60/120.C2.R.PGC Scale

Product Description

Scale WLY for statistic control

Scale WLY is intended to fast and precise determination of mass in laboratory and industrial conditions. The model line is the response for growing market demands concerning simple operation and maximum automation of the weighing process. The scales enables cooperation with barcode scanner, printer, label printer, RFID readers and standard PC devices (mouse, keyboard, USB storage device).

Design and functionality

All WLY scales is equipped with stainless weighing pan, TFT 5,7'' colourful touch screen and membrane keyboard. As an option the scale enables connection of an additional weighing platform to the terminal. The following functions are available:

programmable proximity sensors,

programmable printout templates,

programmable text information for scale's operation,

printouts.

Scale WLY/PGC is equipped with modules that put packaged products control into practice. The module is supported by database containing products and operators lists. A control started by the scale is automatically stopped after controlling pre-defined quantity of packages (samples). Number of the packages is fixed by scales program depending on product batch size. Scales are equipped with 5,7" colourful, graphic touch screen display for previewing information concerning currently performed control and its result.

Scale requires two staged verification process. Due to the influence of gravitational acceleration force the scale has to be adjusted on use site.

Control cycle runs according to the following scheme:

operator choice,

product choice,

control start,

acquiring weighing records,

automatic control end after certain packages number,

control report print.

Each carried out control is ended with a final report containing all information that is necessary for pre-packaged products control report. The report is automatically saved in scale memory and at the same time it can be printed by printer connected to scale.

Scale coupling with computer program enables:

keeping weighing records from successive weighments in the database,

automatic printout of control processes from computer software level,

sending user defined codes from scale to computer software; the codes match weighed product (product code, operator code, batch quantity, batch no., control Start/Stop),

defining product codes and their descriptions (names) from the level of computer program, therefore user can assign an individual product name suitable for the company's branch.

The purpose of the scale is the packaged goods control (PGC), so remember that verification (legalization) is necessary. We recommend ordering a scale with a proper verification (legalization).

Item Stats

Product details

| Functions | Dosing, Labelling, Plus/Minus Control, Percent Weighing, Totalizing, Parts counting, Peak hold, Formulation, Newton unit measurement, Statistics, Checkweighing, IR sensors, Animal weighing, Differential weighing, Packaged Goods Control, ALIBI Memory |

About QuestPair

Our Mission

QuestPair is Europe's leading platform for scientific equipment, connecting researchers and organizations with verified suppliers of both new and pre-owned laboratory instruments in the biotech and material science industry. Our aim is to make the procurement of scientific instruments more efficient, cost-effective, and reliable, so that laboratories can focus on advancing science rather than searching equipment and negotiating deals.

Why Choose Us

Founded by scientists for scientists, we understand your challenges. Our AI-powered platform offers transparent pricing, verified quality, and expert support, ensuring you find the perfect equipment for your research needs.

Verified Quality

Every piece of equipment undergoes thorough verification by our expert team, ensuring reliability and performance.

Cost Efficiency

Access both new and premium pre-owned equipment, saving up to 40% without compromising on quality.

Expert Support

Our dedicated team provides personalized guidance throughout your equipment procurement journey.

Ready to Transform Your Research?

Join thousands of biotech scientists who trust QuestPair for their equipment needs.

What customers think about QuestPair

Brilliant service. Everything arrived and was exactly as expected

Jon Welburn

Great customer service! Got me great options for the equipment I was looking for and in a timely manner.

Pamela

Space Lab Technologies, LLCHarm is very responsive to help me find the right equipment. The product I received is in a good condition.

Ph.D. Hsin-Wen Liang

Northeastern UniversityFrom €1,952.00ex. VAT

In Stock

Get a quote within one business day

Verified equipment

Trusted warranties & returns

Safe payment and fast delivery

Didn't find what you're looking for?

Our sales team specializes in sourcing custom and hard-to-find products to meet your exact specifications. Submit a request for a tailored quote.

Frequently Asked Questions

Is this equipment new or refurbished?

How long does shipping take?

What about warranty and returns?

Why request a quote?

Need help choosing the right tool?

- Accurate policy information specific to your chosen product

- Clear understanding of warranty coverage and terms

- Detailed return policy explanation

- Transparent shipping options and costs

Customer Service

Here to help you with: Product Inquiries, Shipping & Support, Technical Support, Business Inquiries and Press.

We are available to assist you Mon-Fri, 10am - 5pm CET.