Offering the best quotes for your research!

New and used scientific instruments

🚚 Shipping Worldwide 🌎

✉️ info@questpair.com

Do you have items to sell? Post them on QuestPair and reach thousands of potential buyers!

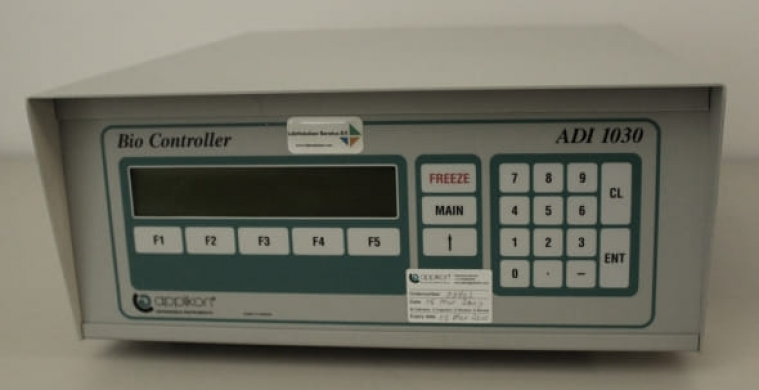

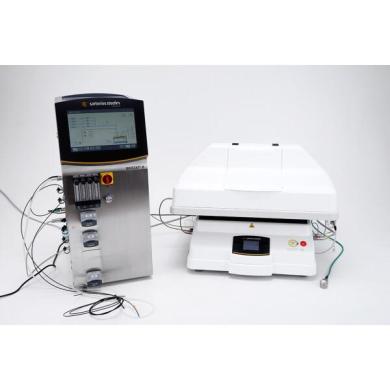

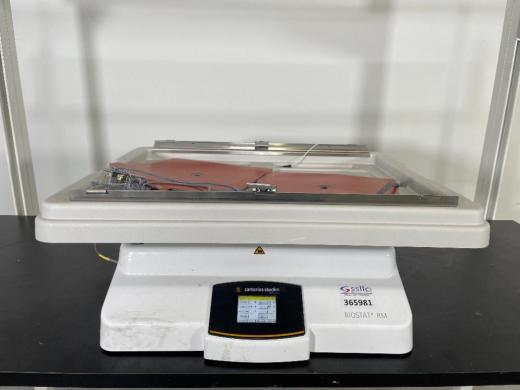

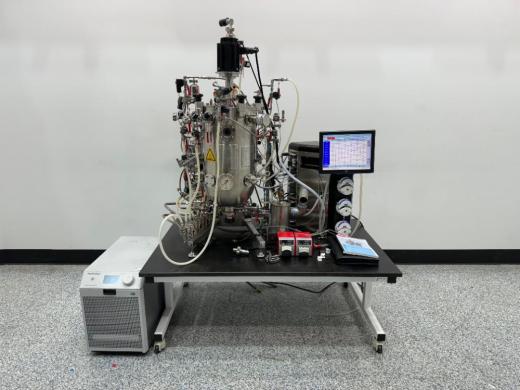

Post New ItemFermenters / bioreactors

Bioreactors are specially designed vessels or systems to sustain biologically active processes. Sometimes, bioreactors can be simple vessels in which a reaction is carried out with the help of microorganisms. Often, bioreactors have temperature and atmosphere control to adjust gas concentration or maintain aerobic or anaerobic conditions. One example of a bioreactor is a fermenter to extract energy from carbohydrates

Didn't find what you're looking for?

Our sales team specializes in sourcing custom and hard-to-find products to meet your exact specifications.

Extensive supplier network

Quality guaranteed

Dedicated support

Didn't find what you're looking for?

Our sales team specializes in sourcing custom and hard-to-find products to meet your exact specifications.

Extensive supplier network

Quality guaranteed

Dedicated support

Didn't find what you're looking for?

Our sales team specializes in sourcing custom and hard-to-find products to meet your exact specifications.

Extensive supplier network

Quality guaranteed

Dedicated support

Customer Service

Here to help you with: Product Inquiries, Shipping & Support, Technical Support, Business Inquiries and Press.

We are available to assist you Mon-Fri, 10am - 5pm CET.